Royal cheese tradition

with innovation

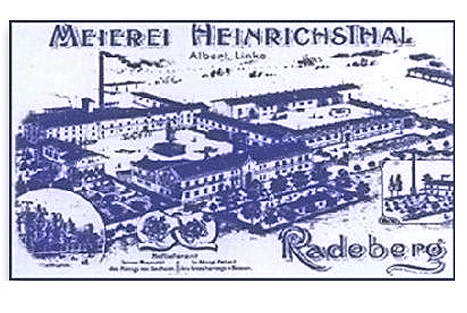

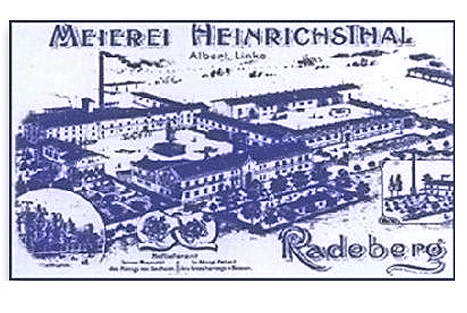

Heinrichsthaler Milchwerke GmbH in Radeberg near Dresden is one of the leading German cheese manufacturers with a long tradition. The company was founded in 1880 as a dairy in idyllic Heinrichsthal and produced the first German Camembert in 1884. As the Radeberg dairy cooperative, the company was the largest producer of soft, semi-hard and hard cheese in the GDR.

Today, the dairy is a modern, medium-sized company that continuously invests in the expansion of production facilities and the extension of capacities and product variety. It builds on the wealth of experience of many generations and draws from this the ideas for a wide range of top-quality Heinrichsthal products.

2020

One of the largest dairies in Germany

Heinrichsthaler Milchwerke GmbH celebrates its 140th anniversary, and the new warehouse and logistics centre was opened at the same time.

2020

19th June 2010

Modernisation with environmental awareness

By integrating indirect cooling and connected heat recovery, Heinrichsthaler uses environmentally friendly refrigeration technology. A new type of photovoltaic system was installed on the roof of the distribution centre. This highly efficient technology captures the maximum amount of sunlight and converts it into electrical energy to supply the plant.

19th June 2010

2008

Milk producer certified

The certification of the factory and the milk producers according to DIN EN ISO 9001 2008 documents the high technological standard of Heinrichsthaler Milchwerke GmbH. The milk used to make the cheese comes from around 60 farms in the region of eastern Saxony and southern Brandenburg.

2008

2007

Cheese with an environmental balance

Heinrichsthaler Milchwerke has been a member of the Saxony Environmental Alliance since 2007. Under the motto "ecologically exemplary - economically successful", the company takes measures to save energy and contributes to improving immission protection.

2007

2004

IFS certifcation

Since 2004, Heinrichsthaler Milchwerke GmbH has also been certified according to the International Food Standard (IFS). The IFS is a seal of quality recognised throughout Europe, which was established by the European food retail trade.

2004

2003

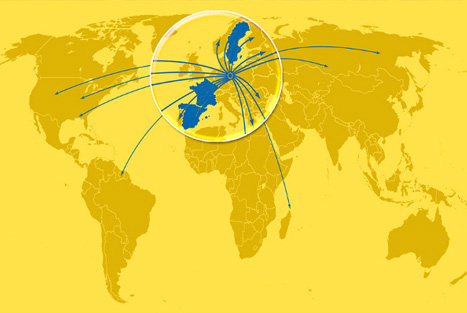

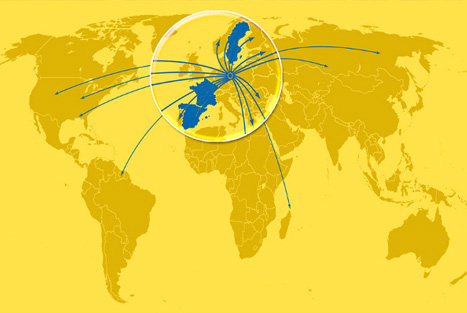

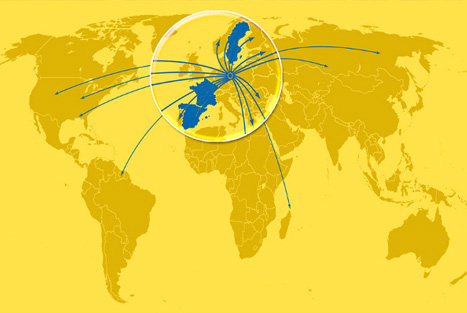

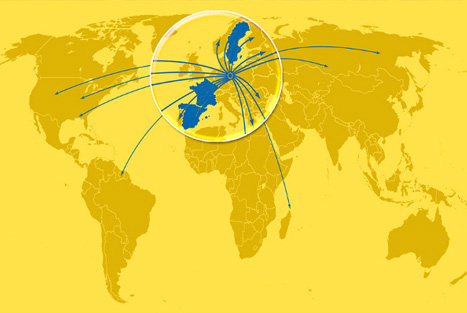

Focus export

In 2003, almost 30 per cent of production already goes outside the country (Europe, USA, Africa). The European export regions include typical cheese countries such as Switzerland, France and Spain. From 2004, the focus will also be on the Scandinavian market.

2003

2000

Change of management

Uwe Lammeck takes over the management. In the expansion of semi-hard cheese production, the company operates in three segments - firstly for the classic food retail trade with the standard products Gouda, Edam, Tilsiter or butter cheese, and secondly in the premium segment with specialities such as fenugreek cheese, wild garlic or Emmentaler. Thirdly, the export sector was strongly expanded.

2000

1992

The turning point for Heinrichsthaler

Heinrichsthaler Milchwerke GmbH is founded. Initially, the cooperative continued to operate with the 46 largest milk suppliers. Signs of development and quality awareness are the "Markenqualität aus Deutschen Landen" seal of quality and numerous DLG medals and prizes.

1992

1947

Time of the cooperatives

The VdgB dairy cooperative in Radeberg was founded in 1947. The daily milk supply was 15,000 litres, from which an average of 350 kilograms of butter, 400 kilograms of skimmed cheese and 300 kilograms of cottage cheese were produced, as well as 120 kilograms of lactose and 1,000 litres of whole and skimmed drinking milk.

On 1 July 1960, the dairy cooperatives of Radeberg, Arnsdorf, Burkau, Lehndorf and Leutewitz were merged to form a VdgB joint enterprise.

Two years later, the dairy engineer and long-time manager of the Großenhain dairy cooperative, Winrich Lammeck, took over the Heinrichsthal dairy as plant manager and managing director.

In GDR times, the dairy was the largest cheese dairy for soft, semi-hard and hard cheese as well as the most effective apprentice training centre with 40 apprenticeship places and enjoyed a very good reputation as a practical training company for college and technical students in the dairy industry. Translated with www.DeepL.com/Translator (free version)

On 1 July 1960, the dairy cooperatives of Radeberg, Arnsdorf, Burkau, Lehndorf and Leutewitz were merged to form a VdgB joint enterprise.

Two years later, the dairy engineer and long-time manager of the Großenhain dairy cooperative, Winrich Lammeck, took over the Heinrichsthal dairy as plant manager and managing director.

In GDR times, the dairy was the largest cheese dairy for soft, semi-hard and hard cheese as well as the most effective apprentice training centre with 40 apprenticeship places and enjoyed a very good reputation as a practical training company for college and technical students in the dairy industry. Translated with www.DeepL.com/Translator (free version)

1947

1945

Reconstruction

After the end of the Second World War, further reconstruction of the Heinrichsthal dairy began in 1945. Despite partially destroyed machinery and equipment, a small production of cheese, butter, quark and drinking milk could be started. The business then fell under the administration of the Russian commandant's office, the owners were expropriated, the existing machinery and equipment dismantled and transported (as reparations) to the Soviet Union.

1945

1925

25th anniversary

On 1 July 1925, the company celebrated its 25th anniversary together with a total of 50 employees.

By 1930, a total of 6 sales outlets existed. Albert Linke's daughter Marga succeeded in cultivating the pure cultures needed for cheese ripening in the company's own laboratory.

As early as 1893 and again after 1920, Heinrichsthal had paid attention to a certain kind of "quality management", which culminated in the company's certification according to DIN EN ISO 9001 in 1996.

Daily milk deliveries rose from about 4,000 litres in 1900 to more than 15,000 litres in the 1930s/40s. In 1950, 27,000 litres of raw milk were processed, in 1960 about 60,000 litres.

By 1930, a total of 6 sales outlets existed. Albert Linke's daughter Marga succeeded in cultivating the pure cultures needed for cheese ripening in the company's own laboratory.

As early as 1893 and again after 1920, Heinrichsthal had paid attention to a certain kind of "quality management", which culminated in the company's certification according to DIN EN ISO 9001 in 1996.

Daily milk deliveries rose from about 4,000 litres in 1900 to more than 15,000 litres in the 1930s/40s. In 1950, 27,000 litres of raw milk were processed, in 1960 about 60,000 litres.

1925

1914

Outbreak WW1

However, the outbreak of the First World War in the summer of 1914 put a stop to the company's prosperous prospects for the future.

1914

1904

Camembert success story

As early as 1904, two developments promoted the production and shipment of Brie and Camembert: attempts were made to stabilise the ripening process of these cheeses through germ cultures. At the same time, a sterilisation process was developed that made it possible to ship Camembert overseas in a tropical-safe condition - whereupon a separate export department soon had to be set up. (Source: Dipl.-Soz. Helmer Pardun, 2005)

1904

1904

Heinrichsthal becomes property

In April 1904, Albert Linke acquired the Heinrichsthal property and terminated the existing partnership agreements.

1904

1893

Royal ascent

In February 1893, the Heinrichsthal dairy was awarded the title of "Royal Saxon Court Supplier" and in June of the same year a second as Court Supplier to the Grand Duke of Hesse. (Source: Dipl.-Soz. Helmer Pardun, 2005)

1893

1885

New leadership qualities

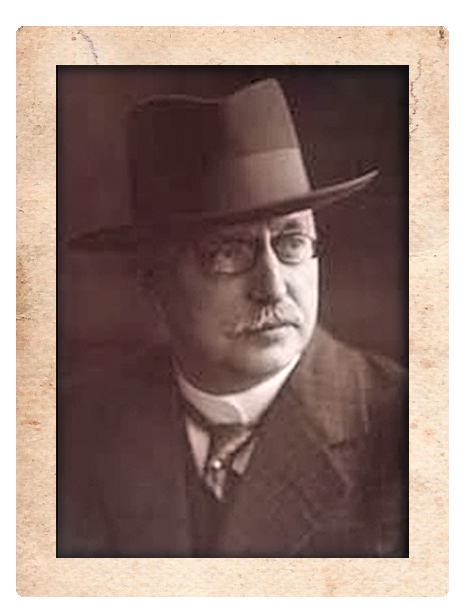

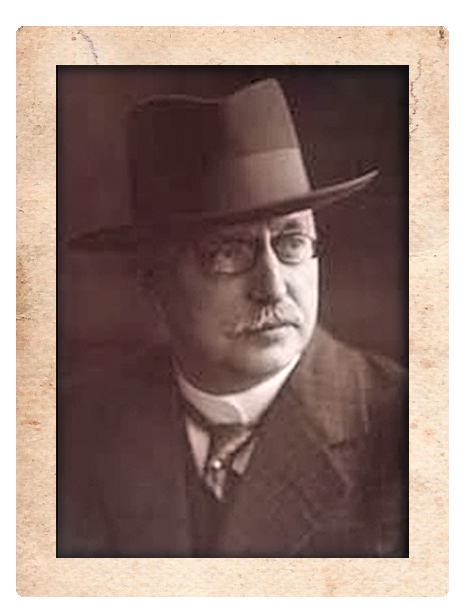

On 1 July 1885 Albert Linke became commercial manager of the expanding Heinrichsthal company. In the meantime, whey utilisation and the production of remedies from whey were patents of the Heinrichsthal dairy.

In 1886, the dairy received two gold and one silver medal as prizes in a nationwide competition organised by the German Dairy Association (Kiel), and in the same year the company was expanded into a model cheese dairy.

On 16 May 1888, the company became the "Meierei Heinrichsthal H.E.L. Prinz", with Albert Linke now holding "procuration". With this new beginning, milk deliveries were increased, production was expanded, sales were increased and business connections were developed. Four years later Albert Linke joined the company as a partner, which was then called "Meierei Heinrichsthal Prinz & Linke".

On 16 May 1888, the company became the "Meierei Heinrichsthal H.E.L. Prinz", with Albert Linke now holding "procuration". With this new beginning, milk deliveries were increased, production was expanded, sales were increased and business connections were developed. Four years later Albert Linke joined the company as a partner, which was then called "Meierei Heinrichsthal Prinz & Linke".

1885

1886

Woman power

From 1886 onwards, the school developed from an educational institution into a prosperous production company. Agathe Zei's husband managed the dairies of Bautzen and Löbau, which she also founded.

1886

1884

Agathe Zeis & the french tatent for Camember

Agathe Zeis then went to France to acquire the theoretical knowledge for this. In the course of producing Camembert and Brie, she acquired the French patent for it only four years after founding the dairy - and made Heinrichsthal the birthplace of the German version of these popular cheeses.

1884

1881

Initiation of the vision

In 1881, on the occasion of the dairy's participation in an agricultural exhibition in Radeberg, the sovereign, Albert of Saxony, enquired about the possibilities of producing Camembert and Brie.

1881

1880

Foundation of the place of action

In 1880, Agathe Zeis founded the Heinrichsthal dairy as a model and training dairy for agricultural daughters.

1880

2020

One of the largest dairies in Germany

Heinrichsthaler Milchwerke GmbH celebrates its 140th anniversary, and the new warehouse and logistics centre was opened at the same time.

2020

19th June 2010

Modernisation with environmental awareness

By integrating indirect cooling and connected heat recovery, Heinrichsthaler uses environmentally friendly refrigeration technology. A new type of photovoltaic system was installed on the roof of the distribution centre. This highly efficient technology captures the maximum amount of sunlight and converts it into electrical energy to supply the plant.

19th June 2010

2008

Milk producer certified

The certification of the factory and the milk producers according to DIN EN ISO 9001 2008 documents the high technological standard of Heinrichsthaler Milchwerke GmbH. The milk used to make the cheese comes from around 60 farms in the region of eastern Saxony and southern Brandenburg.

2008

2007

Cheese with an environmental balance

Heinrichsthaler Milchwerke has been a member of the Saxony Environmental Alliance since 2007. Under the motto "ecologically exemplary - economically successful", the company takes measures to save energy and contributes to improving immission protection.

2007

2004

IFS certifcation

Since 2004, Heinrichsthaler Milchwerke GmbH has also been certified according to the International Food Standard (IFS). The IFS is a seal of quality recognised throughout Europe, which was established by the European food retail trade.

2004

2003

Focus export

In 2003, almost 30 per cent of production already goes outside the country (Europe, USA, Africa). The European export regions include typical cheese countries such as Switzerland, France and Spain. From 2004, the focus will also be on the Scandinavian market.

2003

2000

Change of management

Uwe Lammeck takes over the management. In the expansion of semi-hard cheese production, the company operates in three segments - firstly for the classic food retail trade with the standard products Gouda, Edam, Tilsiter or butter cheese, and secondly in the premium segment with specialities such as fenugreek cheese, wild garlic or Emmentaler. Thirdly, the export sector was strongly expanded.

2000

1992

The turning point for Heinrichsthaler

Heinrichsthaler Milchwerke GmbH is founded. Initially, the cooperative continued to operate with the 46 largest milk suppliers. Signs of development and quality awareness are the "Markenqualität aus Deutschen Landen" seal of quality and numerous DLG medals and prizes.

1992

1947

Time of the cooperatives

The VdgB dairy cooperative in Radeberg was founded in 1947. The daily milk supply was 15,000 litres, from which an average of 350 kilograms of butter, 400 kilograms of skimmed cheese and 300 kilograms of cottage cheese were produced, as well as 120 kilograms of lactose and 1,000 litres of whole and skimmed drinking milk.

On 1 July 1960, the dairy cooperatives of Radeberg, Arnsdorf, Burkau, Lehndorf and Leutewitz were merged to form a VdgB joint enterprise.

Two years later, the dairy engineer and long-time manager of the Großenhain dairy cooperative, Winrich Lammeck, took over the Heinrichsthal dairy as plant manager and managing director.

In GDR times, the dairy was the largest cheese dairy for soft, semi-hard and hard cheese as well as the most effective apprentice training centre with 40 apprenticeship places and enjoyed a very good reputation as a practical training company for college and technical students in the dairy industry. Translated with www.DeepL.com/Translator (free version)

On 1 July 1960, the dairy cooperatives of Radeberg, Arnsdorf, Burkau, Lehndorf and Leutewitz were merged to form a VdgB joint enterprise.

Two years later, the dairy engineer and long-time manager of the Großenhain dairy cooperative, Winrich Lammeck, took over the Heinrichsthal dairy as plant manager and managing director.

In GDR times, the dairy was the largest cheese dairy for soft, semi-hard and hard cheese as well as the most effective apprentice training centre with 40 apprenticeship places and enjoyed a very good reputation as a practical training company for college and technical students in the dairy industry. Translated with www.DeepL.com/Translator (free version)

1947

1945

Reconstruction

After the end of the Second World War, further reconstruction of the Heinrichsthal dairy began in 1945. Despite partially destroyed machinery and equipment, a small production of cheese, butter, quark and drinking milk could be started. The business then fell under the administration of the Russian commandant's office, the owners were expropriated, the existing machinery and equipment dismantled and transported (as reparations) to the Soviet Union.

1945

1925

25th anniversary

On 1 July 1925, the company celebrated its 25th anniversary together with a total of 50 employees.

By 1930, a total of 6 sales outlets existed. Albert Linke's daughter Marga succeeded in cultivating the pure cultures needed for cheese ripening in the company's own laboratory.

As early as 1893 and again after 1920, Heinrichsthal had paid attention to a certain kind of "quality management", which culminated in the company's certification according to DIN EN ISO 9001 in 1996.

Daily milk deliveries rose from about 4,000 litres in 1900 to more than 15,000 litres in the 1930s/40s. In 1950, 27,000 litres of raw milk were processed, in 1960 about 60,000 litres.

By 1930, a total of 6 sales outlets existed. Albert Linke's daughter Marga succeeded in cultivating the pure cultures needed for cheese ripening in the company's own laboratory.

As early as 1893 and again after 1920, Heinrichsthal had paid attention to a certain kind of "quality management", which culminated in the company's certification according to DIN EN ISO 9001 in 1996.

Daily milk deliveries rose from about 4,000 litres in 1900 to more than 15,000 litres in the 1930s/40s. In 1950, 27,000 litres of raw milk were processed, in 1960 about 60,000 litres.

1925

1914

Outbreak WW1

However, the outbreak of the First World War in the summer of 1914 put a stop to the company's prosperous prospects for the future.

1914

1904

Camembert success story

As early as 1904, two developments promoted the production and shipment of Brie and Camembert: attempts were made to stabilise the ripening process of these cheeses through germ cultures. At the same time, a sterilisation process was developed that made it possible to ship Camembert overseas in a tropical-safe condition - whereupon a separate export department soon had to be set up. (Source: Dipl.-Soz. Helmer Pardun, 2005)

1904

1904

Heinrichsthal becomes property

In April 1904, Albert Linke acquired the Heinrichsthal property and terminated the existing partnership agreements.

1904

1893

Royal ascent

In February 1893, the Heinrichsthal dairy was awarded the title of "Royal Saxon Court Supplier" and in June of the same year a second as Court Supplier to the Grand Duke of Hesse. (Source: Dipl.-Soz. Helmer Pardun, 2005)

1893

1885

New leadership qualities

On 1 July 1885 Albert Linke became commercial manager of the expanding Heinrichsthal company. In the meantime, whey utilisation and the production of remedies from whey were patents of the Heinrichsthal dairy.

In 1886, the dairy received two gold and one silver medal as prizes in a nationwide competition organised by the German Dairy Association (Kiel), and in the same year the company was expanded into a model cheese dairy.

On 16 May 1888, the company became the "Meierei Heinrichsthal H.E.L. Prinz", with Albert Linke now holding "procuration". With this new beginning, milk deliveries were increased, production was expanded, sales were increased and business connections were developed. Four years later Albert Linke joined the company as a partner, which was then called "Meierei Heinrichsthal Prinz & Linke".

On 16 May 1888, the company became the "Meierei Heinrichsthal H.E.L. Prinz", with Albert Linke now holding "procuration". With this new beginning, milk deliveries were increased, production was expanded, sales were increased and business connections were developed. Four years later Albert Linke joined the company as a partner, which was then called "Meierei Heinrichsthal Prinz & Linke".

1885

1886

Woman power

From 1886 onwards, the school developed from an educational institution into a prosperous production company. Agathe Zei's husband managed the dairies of Bautzen and Löbau, which she also founded.

1886

1884

Agathe Zeis & the french tatent for Camember

Agathe Zeis then went to France to acquire the theoretical knowledge for this. In the course of producing Camembert and Brie, she acquired the French patent for it only four years after founding the dairy - and made Heinrichsthal the birthplace of the German version of these popular cheeses.

1884

1881

Initiation of the vision

In 1881, on the occasion of the dairy's participation in an agricultural exhibition in Radeberg, the sovereign, Albert of Saxony, enquired about the possibilities of producing Camembert and Brie.

1881

1880

Foundation of the place of action

In 1880, Agathe Zeis founded the Heinrichsthal dairy as a model and training dairy for agricultural daughters.

1880